| Item/Specification | V-60 | V-80 | V-110 | V-130 | V-170 | V-220 | VS-220 | ||||||||||||||||||

| A | B | S | A | B | S | K | A | B | S | O | K | A | B | S | K | A | B | K | A | B | K | A | B | ||

| Injection unit | |||||||||||||||||||||||||

| Screw diameter | mm | 25 | 28 | 25 | 28 | 30 | 25 | 28 | 30 | 35 | 25 | 28 | 35 | 40 | 45 | 28 | 40 | 45 | 50 | 45 | 50 | 55 | 45 | 50 | 55 |

| Shot volume (theoretical) | cm3 | 64 | 80 | 74 | 92 | 106 | 98 | 123 | 141 | 192 | 98 | 123 | 192 | 251 | 318 | 135 | 276 | 350 | 432 | 414 | 511 | 618 | 366 | 452 | 546 |

| Injection weight (ps) | g | 59 | 74 | 68 | 85 | 98 | 90 | 113 | 130 | 177 | 90 | 113 | 177 | 231 | 293 | 125 | 254 | 322 | 397 | 380 | 470 | 568 | 337 | 415 | 503 |

| oz | 2.1 | 2.6 | 2.4 | 3 | 3.4 | 3.2 | 4 | 4.6 | 6.2 | 3.2 | 4 | 6.2 | 8.2 | 10.3 | 4.4 | 9 | 11.4 | 14 | 13.4 | 16.6 | 20 | 11.9 | 14.7 | 17.7 | |

| Injection stroke | mm | 130 | 130 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 220 | 220 | 220 | 220 | 260 | 260 | 260 | 230 | 230 | 230 |

| Injection pressure | Mpa | 2880 | 2296 | 3328 | 2653 | 2311 | 3341 | 3031 | 2640 | 1940 | 3341 | 2663 | 2802 | 2145 | 1695 | 3061 | 2880 | 2276 | 1843 | 2987 | 2419 | 1999 | 1521 | 1231 | 1018 |

| Injection rate | g/sec | 56 | 71 | 96 | 61 | 70 | 108 | 63 | 72 | 99 | 108 | 135 | 91 | 119 | 151 | 158 | 125 | 158 | 196 | 121 | 149 | 180 | 530 | 530 | 530 |

| Plasticizing capacity | g/sec | 7 | 10 | 9 | 10 | 12 | 11 | 8 | 9 | 12 | 8 | 12 | 11 | 17 | 23 | 10 | 18 | 24 | 31 | 22 | 19 | 37 | 21 | 16 | 35 |

| Screw speed | rpm | 314 | 314 | 395 | 251 | 251 | 368 | 195 | 195 | 195 | 291 | 291 | 206 | 206 | 206 | 241 | 241 | 241 | 241 | 179 | 179 | 179 | 191 | 191 | 191 |

| Nozzle contact force | ton | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 6.2 | 6.2 | 6.2 | 6.2 | 6.2 | 6.2 |

| Nozzle move stroke | mm | 245 | 245 | 245 | 245 | 300245 | 300 | 300 | 300 | 300 | 380 | 370 | 370 | 380 | 380 | 380 | 380 | 380 | 380 | 400 | 400 | 400 | 400 | 400 | 400 |

| Clamping unit | |||||||||||||||||||||||||

| Clamping force | ton | 60 | 80 | 110 | 130 | 170 | 220 | 220 | |||||||||||||||||

| Mold opening stroke | mm | 260 | 330 | 370 | 410 | 460 | 520 | 520 | |||||||||||||||||

| Max.daylight between platens | mm | 610 | 730 | 820 | 910 | 1010 | 1170 | 1170 | |||||||||||||||||

| Min.mold height | mm | 100 | 130 | 150 | 150 | 180 | 200 | 200 | |||||||||||||||||

| Max.mold height | mm | 350 | 400 | 450 | 500 | 550 | 650 | 650 | |||||||||||||||||

| Space between tie bars (HxV) | mm | 320x320 | 365x365 | 410x410 | 460x460 | 510x510 | 560x560 | 560x560 | |||||||||||||||||

| Overal size of platens (HxV) | mm | 480x480 | 560x560 | 620x620 | 675x675 | 750x750 | 820x820 | 820x820 | |||||||||||||||||

| Ejector tonnage | ton | 3.1 | 3.8 | 3.8 | 3.8 | 3.8 | 6.2 | 6.2 | |||||||||||||||||

| Ejector stroke | mm | 80 | 100 | 130 | 140 | 150 | 160 | 160 | |||||||||||||||||

| Others | |||||||||||||||||||||||||

| Max.pump pressure | Mpa | 16 | 16 | 16 | 16 | 16 | 16 | 16 | |||||||||||||||||

| Heater power | KW | 5.5 | 6.5 | 7 | 7 | 6.5 | 7 | 7 | 7 | 6.5 | 6.5 | 8 | 8 | 8 | 7 | 9 | 9 | 9 | 11.5 | 11.5 | |||||

| Pump motor power | KW | 13 | 18.5 | 13 | 13 | 22 | 15 | 15 | 15 | 22 | 22 | 18.5 | 18.5 | 18.5 | 22 | 22 | 22+7.5 | ||||||||

| Oil tank cubage | L | 170 | 250 | 250 | 300 | 400 | 500 | 500 | |||||||||||||||||

| Machine dimension (LxWxH)) | m | 38x1.2x1.5 | 4.3x1.2x1.6 | 4.6x1.3x1.6 | 4.9x1.4x1.7 | 5.3x1.4x1.8 | 5.8x1.5x1.9 | 5.8x1.65x1.95 | |||||||||||||||||

| Machine weight | T | 2.8 | 3.5 | 4.5 | 5.3 | 6.4 | 8.1 | 8.1 | |||||||||||||||||

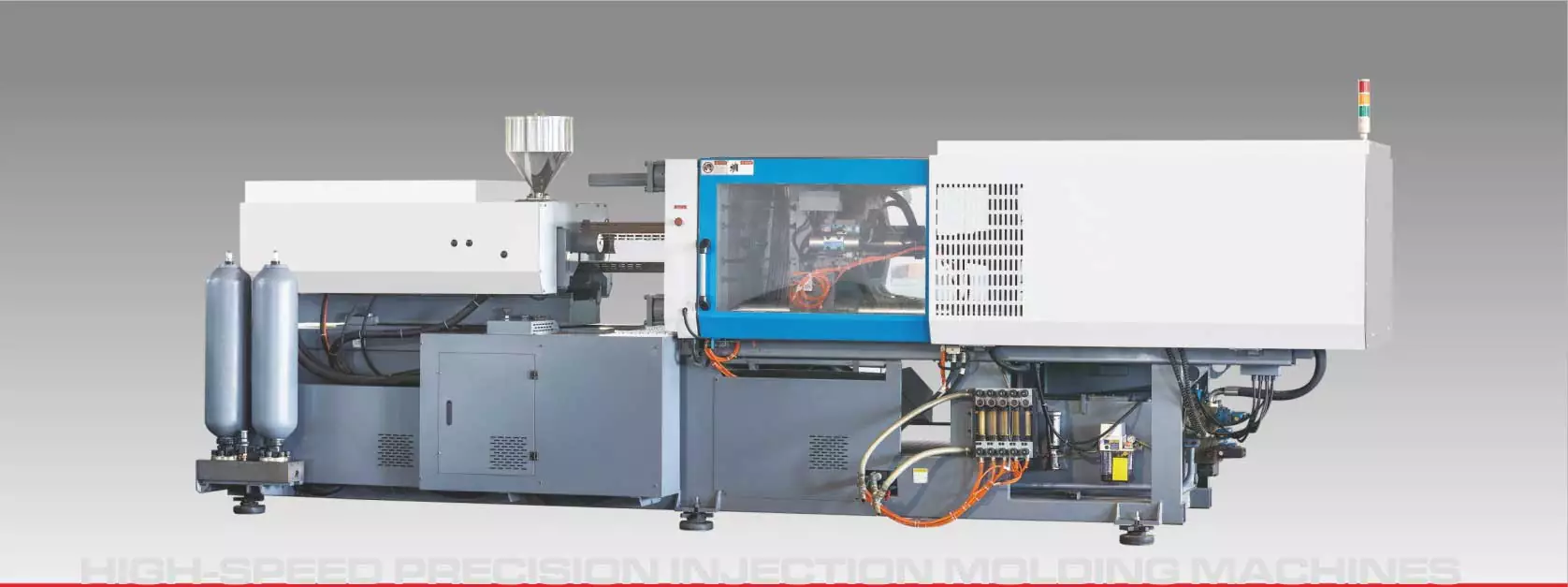

These series machines take the accumulator to help inject, which having hight cost perfomance improve the speed; adding mould platen ope ejection synchronous function, quicken the machine circle time, higher the efficiency, and especially suitable for the ultrathin, precious and complicated products.

Clamping part

Injection part

Hydraulic part

Control part

Вы можете заказать полный комплекс оборудования, необходимый для организации производства, который будет оптимально просчитан и адаптирован под Ваши задачи с техническим и технологическим обеспечением.

Мы производим шеф-монтаж, пусконаладочные работы, гарантийное и послегарантийное сопровождение. Наши специалисты проведут консультации по правильной подготовке производственного помещения для установки оборудования и прокладке необходимых коммуникаций, а также осуществят обучение персонала.

|

|

|

|

|